Environmental sustainability: water purification

ICAB La Fiammante has taken sustainability, environmental, social and economic, as its own brand project value and is investing many human and economic resources in its pursuit.

The production process of canned tomatoes has a low environmental impact and fortunately does not generate toxic-harmful pollutants, but it has some critical issues related to sustainability. Among the most impactful items we must consider the consumption of water and pesticides in the fields, the production of waste and scrap in the processing, and energy consumption.

Given the daily quantities of tomatoes processed, ICAB produces about 2,000 quintals per day of waste and scrap and is implementing practices to decrease their production, but more importantly procedures to reuse some of them in a circular economy perspective.

The major wastes are represented by:

husks and seeds (about 300 q.l/day)

- plant stems

- topsoil (about 400 q/day)

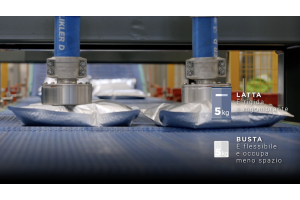

- aluminum

- plastic

- plastic film

- glass

The husks and seeds are destined for livestock use and supplied to shepherds in the Salerno area; they could theoretically be supplied to biogas plants, but priority is given to another sector that is vital to the area.

A compost, very similar to peat in some of its chemical and physical characteristics, is obtained from the plant stems and used as a soil conditioner (fertilizer) for agronomic or floricultural uses.

Tomatoes (edible, edible produce) delivered to canneries arrive soiled with soil and foliage so the first action the company must take, is to wash the raw material. The topsoil that is recovered, which was present until a few hours earlier in the production field, could theoretically be reused in agronomic use, but regulations assimilate it to waste and it must be disposed of as such. Sewage treatment plants are required to dispose of it in the form of sands or sludge. The Campania Region in 2021 took a first step forward by publishing a decree allowing its partial reuse, but hopefully more can be done in the future. ICAB La Fiammante has set up a purification and sanitization plant that allows 50% of the wash water to be recovered and the rest to be disposed of as sand or sludge. (See video at the following link: https://vimeo.com/video_depurazione)

In contrast, aluminum, plastic, films and glass are 100% sorted and recovered for recycling.